Custom-Built Snowboard

This work is ongoing and will fill with additional content in the future.

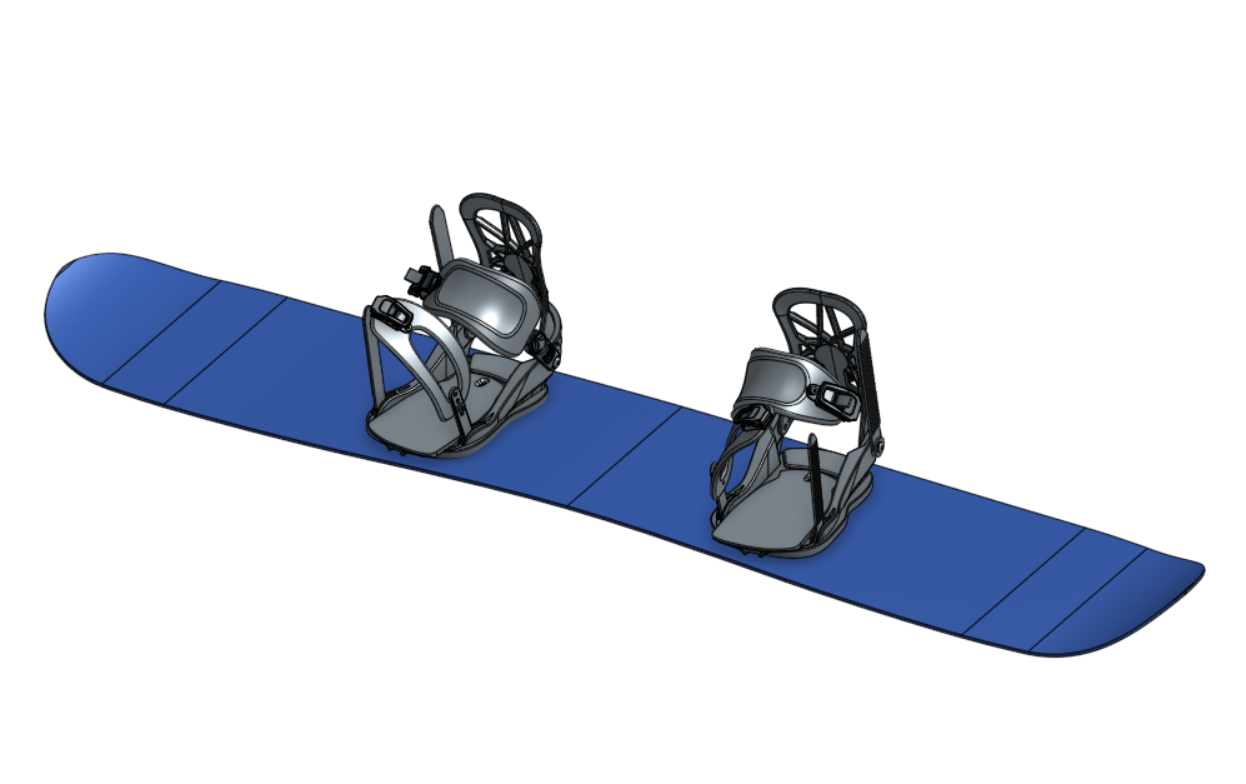

I am designing and manufacturing a fully custom snowboard from scratch, combining engineering with my passion

for snowboarding to create a board that is both technically refined and personally meaningful. This project explores

how material selection, geometry, and structural layering influence ride feel, flex, and durability. The snowboard

features a poplar wood core, wrapped by an urethane resin for moisture protection, reinforced with fiberglass cloth and epoxy resin for rigidity, a polyethylene

(P-tex) base, and a veneer topsheet for UV protection. Each layer’s composition, thickness, and orientation are carefully

engineered to achieve balanced flex, efficient load transfer, and reliable long-term performance.

This project involves shaping a cambered profile and refining the manufacturing process to balance performance with practical

fabrication. I am applying wood shaping and composite layup techniques methods while managing material interfaces. Through

this process, I am strengthening my understanding of material properties, stress distribution, and structural optimization,

connecting my engineering work to my passion for snowboarding. The result is a snowboard engineered for both performance

and manufacturability, combining technical precision with hands-on craftsmanship.

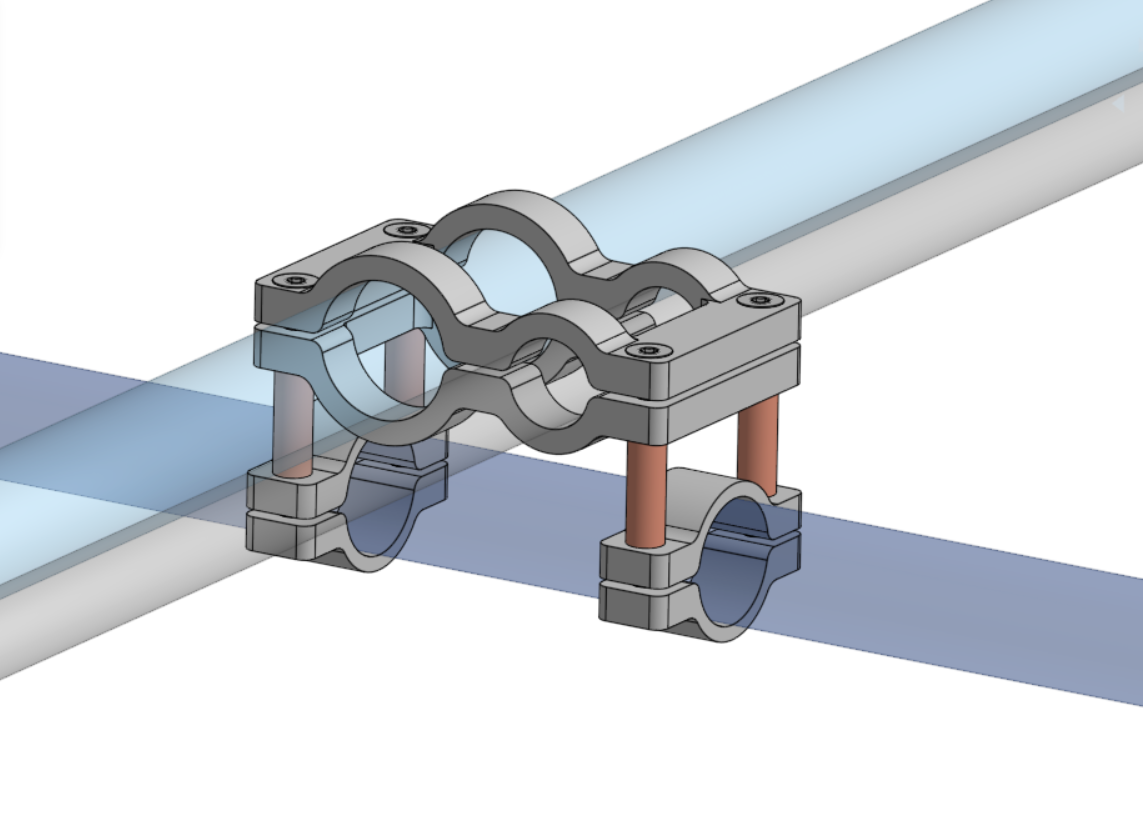

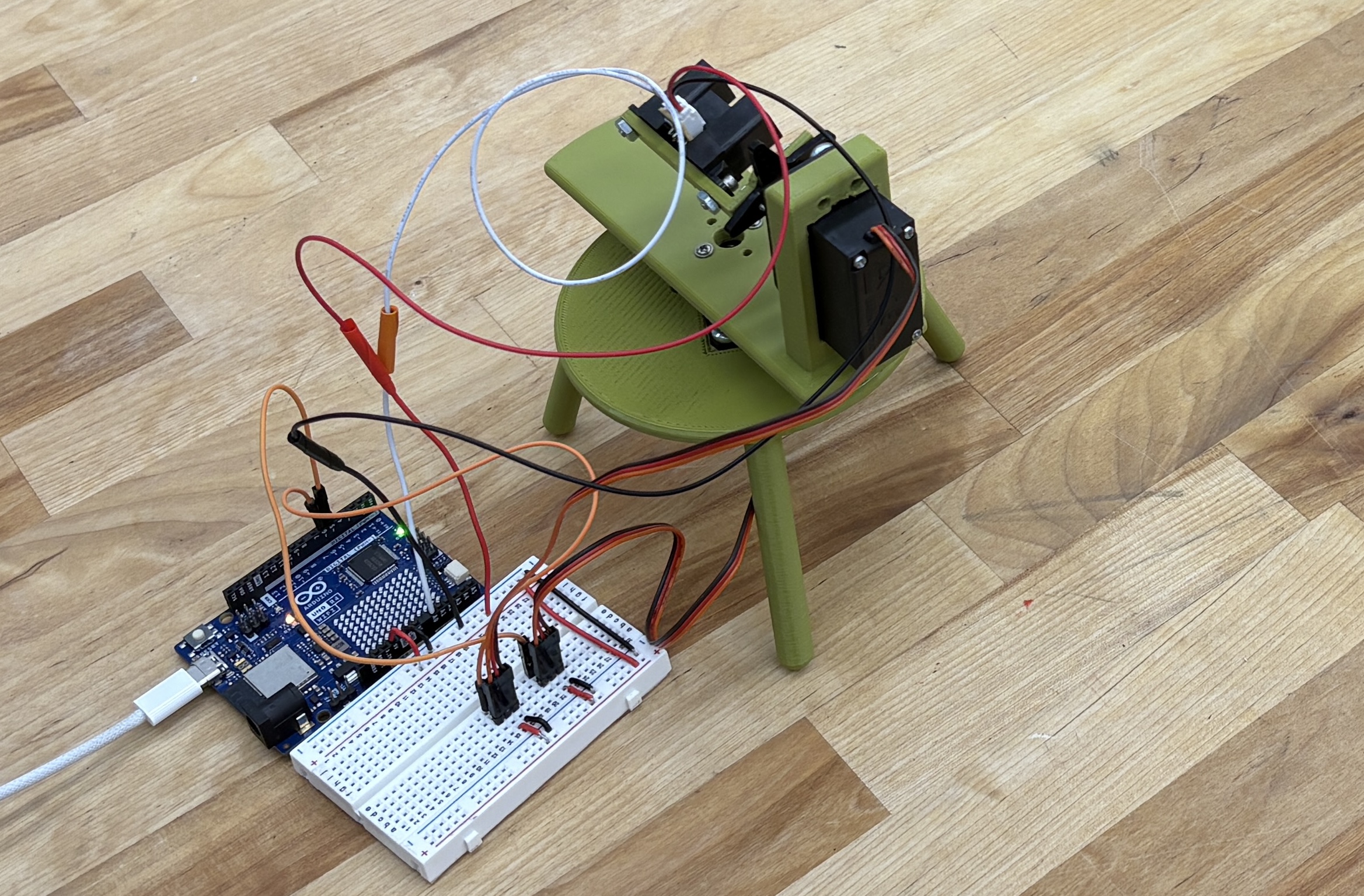

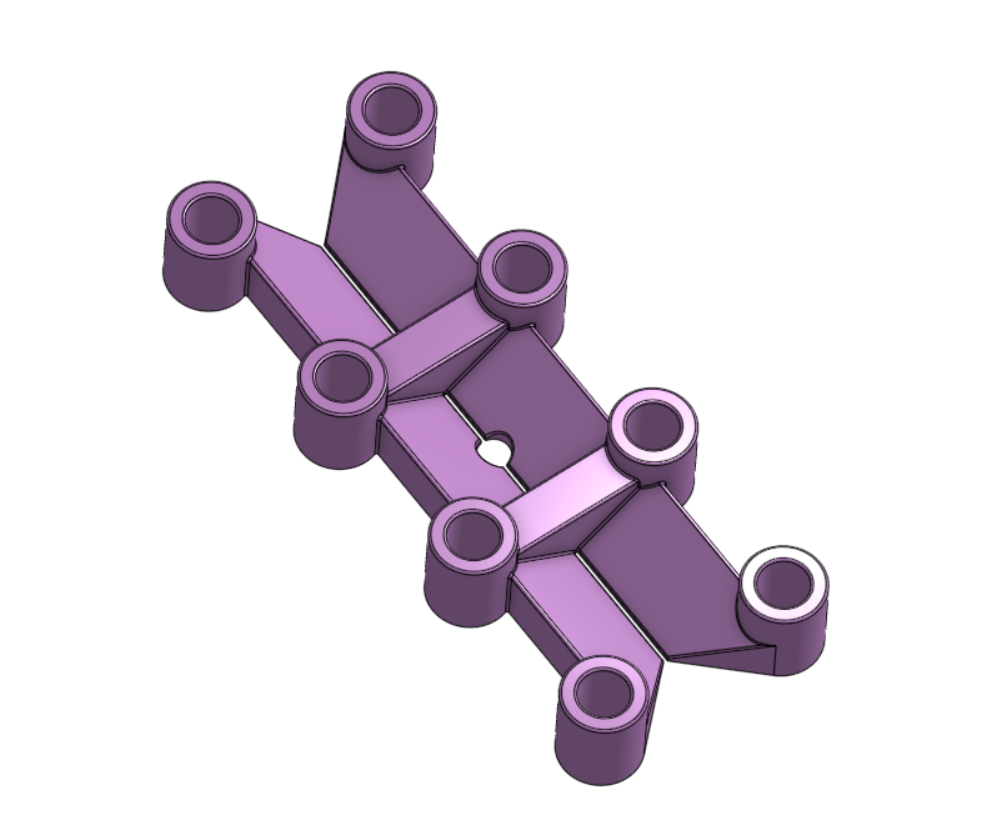

I have designed a couple of 3D printed parts to assist in fabrication, including a drill guide for the binding insert hole seen to the right, as well as a thickness guide.

The thickness guide is attached to the underside of the wooden core as it is passed through the planer, reducing the thickness of the ends of the board for desired flex.

This work is ongoing and will fill with additional content in the future.